Driving Innovation: The Crucial Role of Current Sensor ICs in Modern Automotive Applications

Get valuable resources straight to your inbox - sent out once per month

We value your privacy

Advanced driver-assistance systems (ADAS) and electrification are driving a dramatic revolution in the automotive sector. Electronic components that are precise and trustworthy, with current sensors playing a key role, are at the core of these improvements. This article explores the uses of current sensors in automotive systems, the elements to take into account when selecting a current sensor, and the requirements for product quality.

In-Depth Look at Applications of Current Sensors in Automotive Systems

Numerous automobile systems depend on current sensor ICs, each with specific needs and functions:

- Battery Management Systems (BMS): A BMS's eyes and ears are current sensors, which keep a watch on the current entering and leaving the battery. They offer real-time information on the battery's state of charge and overall health, allowing the BMS to optimize charging and discharging cycles, avoid overcharging or deep draining, and guarantee the battery's longevity. This is especially important for electric vehicles because battery performance directly affects the range and longevity of the vehicle.

- Electric Power Steering (EPS): Current sensors in EPS systems keep track of the current flowing through the motor that helps the driver. Based on the steering input and vehicle speed, the EPS control unit can modify the level of assistance with the help of the sensor's readings. As a result, steering is more responsive and smoother, and it can adjust to various driving situations.

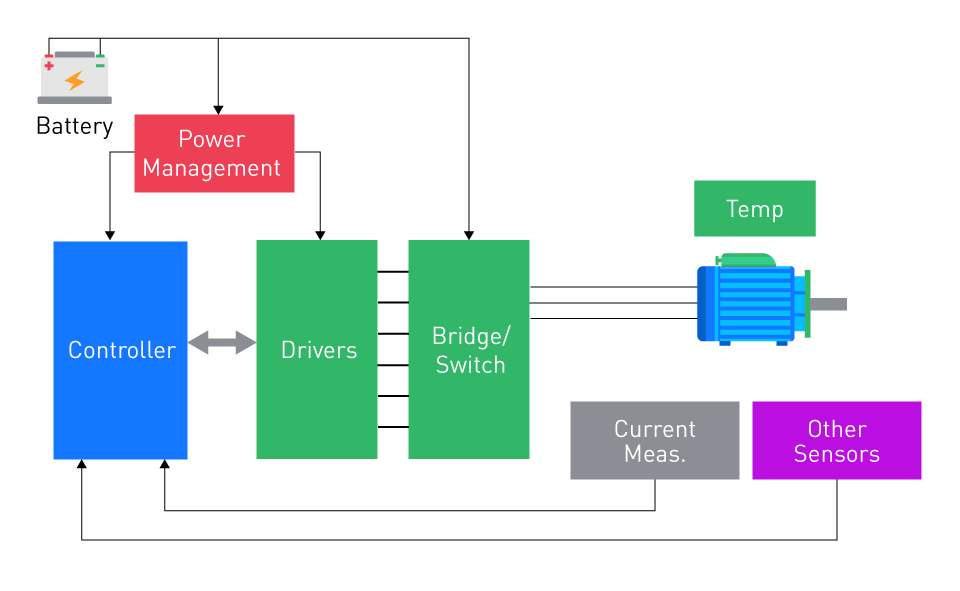

Figure 1 shows a high-level block diagram of a typical EPS implementation and highlights its fundamental components.

Figure 1: A typical EPS system

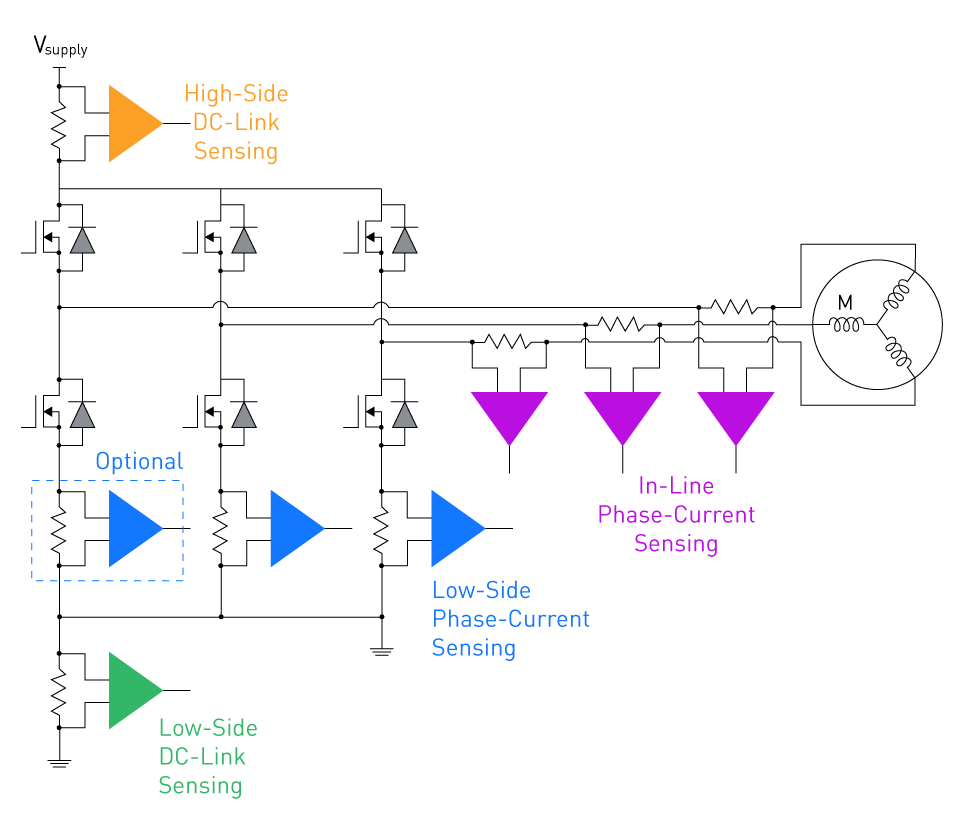

The high-side over-current protection (OCP), low-side OCP, low-side phase current, and in-line phase current are the four alternatives for current sensing in an EPS system (see Figure 2). Which of the four current-measurement choices the system designer chooses will depend on the requirements of the system. It's crucial to precisely track the torque delivered to the steering column and convert it into a vehicle response in order to assure vehicle safety. This torque detection's accuracy is ensured by accurate current measurement.

Figure 2: Circuit diagram showing four potential current-measurement options for three-phase motor implementations

- Electric Vehicle (EV) and Hybrid Electric Vehicle (HEV) Inverters: The inverter, which is at the center of both EVs and HEVs, transforms DC power from the battery to AC power for the electric motor. The inverter systems' current sensors keep an eye on the current flowing through the motor drive circuit and provide feedback that aids in regulating the motor's speed and torque. With smoother acceleration and greater energy utilization, this precise control improves the vehicle's efficiency and performance.

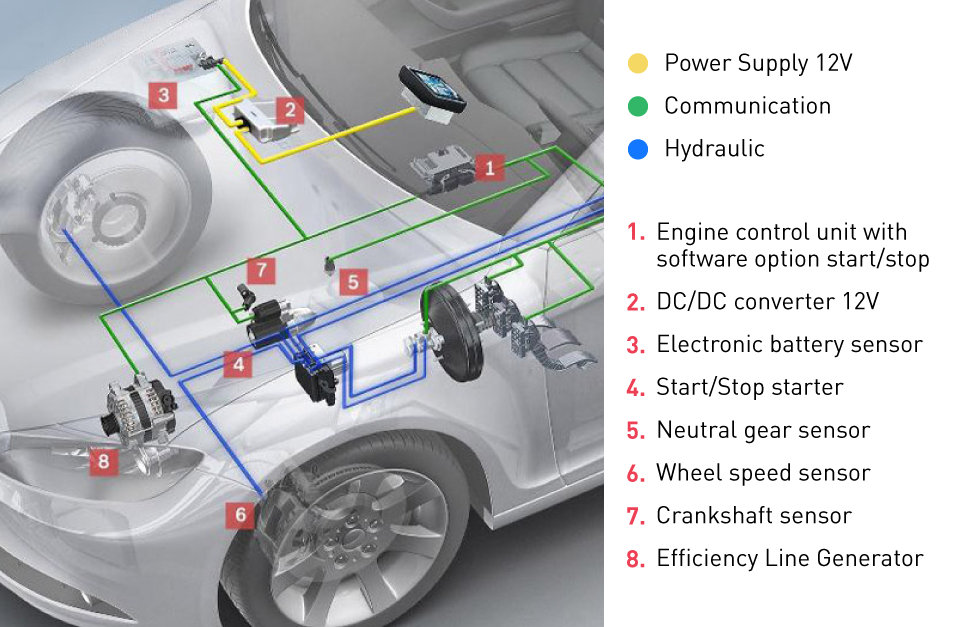

- Start-Stop Systems: Current sensors are used to keep track of the starting motor current in vehicles with start-stop technology. This data assists the start-stop control unit in controlling the starting motor's activity, resulting in a smooth and dependable start-stop operation. Particularly in city driving situations with frequent pauses, this technology improves fuel economy and lowers pollutants.

Figure 3 shows the start-stop system for a vehicle and its components.

Figure 3: The start-stop system of a vehicle

- DC/DC Converters: Vehicles use DC/DC converters to change the voltage of the battery to the voltages needed by various electronic systems. These converters' current sensors keep an eye on the current to ensure effective power conversion and to safeguard the converter from possible harm because of overcurrent situations. This aids in maintaining the electrical systems' optimal performance and saving the battery life.

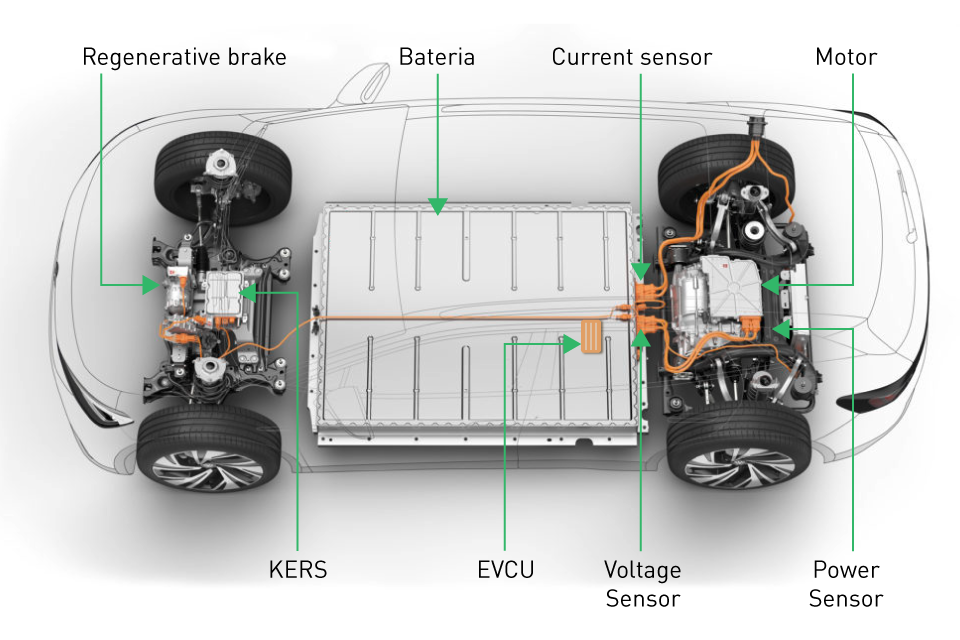

- Regenerative Braking Systems: Regenerative braking systems in EVs and HEVs transform the kinetic energy created during braking into electrical energy, which is then saved in the battery. Current sensors keep track of the current produced during this procedure and provide input that aids in maximizing energy recovery and raising the vehicle's overall efficiency.

Figure 4 shows the parts of an electric vehicle's regenerative braking system.

Figure 4: Regenerative braking system of an electric vehicle

- On-Board Chargers (OBC): The OBC in EVs and plug-in HEVs converts the AC power from the charging station to DC electricity so that the battery may be charged. OBCs' current sensors keep an eye on the charging current and provide information that may be used to manage the charging process, safeguard the battery from potential overcharging, and increase battery longevity.

Current sensor ICs benefit the effectiveness, functionality, and safety of the vehicle in each of these applications. They are also essential to the development of cutting-edge automotive technologies like autonomous driving technology and electrified automobiles.

Choosing the Right Current Sensor IC

A current sensor IC should have the following qualities when choosing one for automotive applications:

- Accuracy: Under all operational circumstances, the sensor ought to deliver precise measurements.

- Bandwidth: The sensor's bandwidth needs to be appropriate for the application. For instance, applications for motor control need more bandwidth than those for battery monitoring.

- Temperature Range: The sensor needs to be dependable across the whole temperature range anticipated in an automobile setting.

- Package Size: The sensor must fit within the application's physical restrictions.

- Isolation: Galvanic isolation between the measured current and the sensor output may be required by the sensor, depending on the application.

- Power Consumption: Lower power consumption is preferred, especially in applications that use batteries.

Adherence to Automotive Quality Specifications

Automotive quality requirements must be taken into account when selecting ICs for automotive applications:

- ISO 26262 - Road Vehicles Functional Safety: This standard guarantees the functionality of electrical and electronic systems in mass-produced cars.

- Automotive Electronics Council (AEC) Q100 and Q200: The integrated circuits and electronic components used in automotive applications must meet these certification requirements.

- IEC 61508 - Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems: Any safety-related system that uses electrical, electronic, or programmable electronic components must adhere to this standard.

- ISO 7637 - Road Vehicles Electrical Disturbances from Conduction and Coupling: It assures that parts will operate correctly even when there are electrical disturbances.

- ISO 11452 - Road Vehicles Component Test Methods for Electrical Disturbances from Narrowband Radiated Electromagnetic Energy: Regardless of the propulsion technology, this standard provides test procedures for parts of passenger automobiles and commercial vehicles.

- ISO 16750 - Road Vehicles Environmental Conditions and Testing for Electrical and Electronic Equipment: This standard outlines testing and recommendations for the particular mounting position on/in road vehicles, as well as probable environmental stressors.

The performance, safety, and dependability of the contemporary sensor ICs in diverse automotive applications are all guaranteed by adherence to these criteria.

Conclusion

All in all, the efficiency, performance, and safety of automobiles are all impacted by current sensor ICs, which are critical to the automotive industry. It's critical to take into account the application-specific requirements, the sensor's features, and the pertinent automotive quality criteria when choosing a current sensor IC. Manufacturers can guarantee that their cars fulfill the highest requirements for quality and safety by doing this.

_______________________

Did you find this interesting? Get valuable resources straight to your inbox - sent out once per month!

技术论坛

Latest activity 4 weeks ago

Latest activity 4 weeks ago

9 回复

9 回复

Latest activity 4 weeks ago

Latest activity 4 weeks ago

50 回复

50 回复

Latest activity 2 months ago

Latest activity 2 months ago

13 回复

13 回复

直接登录

创建新帐号