Wide Bandgap Semiconductors in LLC Converters

The inclusion of broad bandgap semiconductors, notably silicon carbide (SiC) and gallium nitride (GaN), is causing a substantial shift in the world of Inductor-Inductor-Capacitor (LLC) converters. With regard to a number of essential characteristics, these materials are distinct from conventional silicon.

Exploration of Silicon Carbide (SiC) and Gallium Nitride (GaN) Components

In recent years, SiC and GaN semiconductors have become very important parts of power circuits, especially in LLC converters. They are particularly well-suited for applications that include high-frequency and high-power use because they possess distinctive characteristics, such as a stronger breakdown electric field and greater thermal conductivity.

Because SiC components are so well-known for their durability and ability to maintain stability at high temperatures, they are ideally suited for applications in which dependability under extreme conditions is of the utmost importance.

The extraordinary electron mobility of GaN, on the other hand, makes it particularly well-suited for use in high-frequency activities. When it comes to LLC converters, this trait is particularly beneficial because higher switching frequencies can result in designs that are both more compact and more economically efficient.

Impact on Efficiency and Performance

In LLC converters, the utilization of SiC and GaN results in a significant improvement in productivity. In comparison to conventional semiconductors based on silicon, these materials are able to function at higher frequencies while experiencing reduced losses. This is the primary reason for their success. High-frequency operation can reduce the size of passive components like inductors and capacitors, leading to more compact and lightweight designs. Enhanced thermal performance is another benefit that these semiconductors bring to the table. Because of their increased thermal conductivity, they are able to dissipate heat more effectively, which is an essential component in ensuring that the components continue to function well and for a longer period of time.

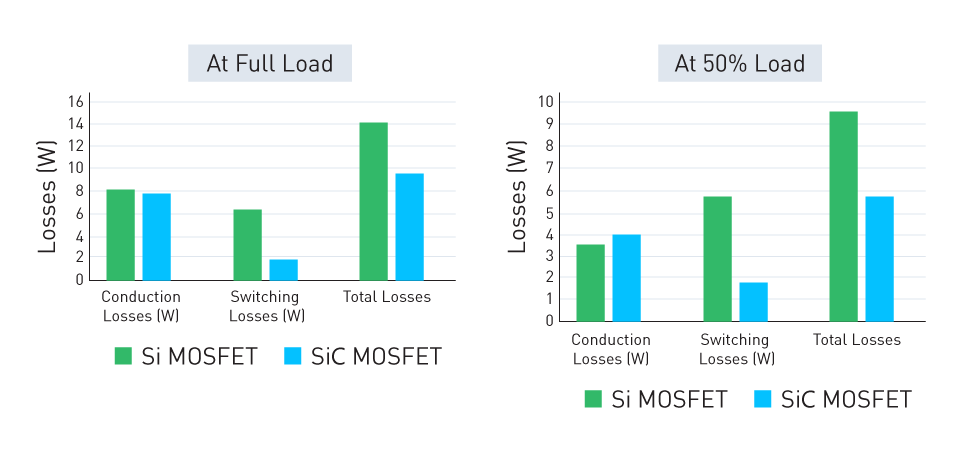

Figure 1: Loss Comparison of SiC- and Si-Based LLC at Full Load and at 50% Load

SiC and GaN components produce decreased switching losses and decreased electromagnetic interference (EMI), which improve the system's overall performance. The end result is that LLC converters are not only more effective, but they are also more dependable and simpler to incorporate into a wide range of applications. Furthermore, the durability of these materials under high voltage and high temperatures extends the operational range of LLC converters. This makes LLC converters ideal for applications that include more demanding requirements.

Digital Control of LLC Converters

The implementation of digital control technology is causing a sea change in the landscape of LLC converters, which is currently undergoing a transformational upheaval. When it comes to the design, operation, and optimization of LLC converters, this movement is not merely a trend; rather, it represents a significant evolution in the field.

Advancements in Digital Control Technologies

The increased precision and flexibility brought about by digital control technology has resulted in the transformation of LLC converters and LLC controllers. The use of digital pulse-width modulation (PWM), which improves control over switching events and consequently raises both efficiency and performance, is a significant development that has enabled significant advancements.

In addition, the utilization of digital signal processors (DSPs) and microcontrollers inside these systems makes it possible to do real-time monitoring and adaptive control. This feature is absolutely essential in order to keep performance at its peak even when the load conditions are constantly shifting. By dynamically responding to changes such as input voltage or load variations, these controllers offer high reliability in applications that are essential to server power supplies and telecommunications infrastructure. These are applications in which consistent performance and minimal operational disturbance are of the utmost importance.

Benefits and Challenges of Implementation

Digital control in LLC converters offers a multitude of advantages. An increase in control precision leads to an improvement in both power management and utility efficiency. Digital controllers have the ability to make dynamic adjustments to the operating parameters in real time, which allows them to optimize performance for a variety of load scenarios while simultaneously decreasing energy waste.

In order to improve the controllers' dependability and safety, digital control systems make it possible for them to have additional capabilities such as self-diagnostics and problem detection. In addition to this, they make it simpler to integrate with other digital systems, which enables power solutions that are both more intelligent and more connected. It is important to note that the move to digital control is not without its difficulties. In order to develop and operate digital systems effectively, one must possess a greater level of skill due to the complexity of these systems. This may increase the amount of time and money required for development.

In addition, the implementation of digital control systems leads to concerns over the integrity of signals, particularly in settings that are characterized by high levels of electromagnetic interference (EMI). Under these circumstances, it is of the utmost importance to guarantee reliable signal processing and communication.

Innovative Design Techniques

Innovative design strategies for LLC converters are becoming increasingly important as power conversion technology continues to push its boundaries. These strategies aim to not only enhance existing systems but also reimagine and reinvent existing approaches to meet the ever-changing requirements of a wide range of applications.

Exploration of Cutting-edge Design Strategies

Monolithic Power Systems (MPS) has made tremendous progress in the field of LLC converters by incorporating cutting-edge design methodologies that are tailored to meet the stringent requirements of contemporary electronics. Our strategy incorporates the use of monolithic integration, which is the process of assembling power components, such as controllers, MOSFETs, and other components that handle power, into a single chip. This integration greatly simplifies the entire design, reduces the physical footprint, and enhances the reliability of the power supply.

Furthermore, MPS has implemented cutting-edge heat management strategies in their monolithic designs, utilizing these methodologies. Due to their construction using high thermal conductivity materials and unique package designs that enhance heat dissipation properties, these LLC converters can handle larger power densities without the risk of overheating. The use of cutting-edge modulation techniques inside its LLC systems further demonstrates MPS's dedication to efficiency. These techniques include synchronized rectification and adaptive dead-time control, among others. These strategies minimize energy loss during power conversion, leading to significant enhancements in the performance and energy efficiency of the systems they power.

Adaptation for Specific Applications

Adapting these cutting-edge design methodologies to their intended applications is essential. The design of LLC converters must adapt to the specific requirements and difficulties associated with each application. For instance, in high-power industrial applications, the focus may be on controlling high current and voltage levels in a dependable manner. On the other hand, in consumer electronics, the focus may be on compactness and efficiency.

LLC converters are required to be able to tolerate vast input voltage ranges and a variety of load circumstances in order to be functional in applications such as electric vehicles and renewable energy systems. In this context, the implementation of new design ideas can significantly enhance the adaptability and efficiency of the power conversion process. Another crucial factor to consider is the integration of LLC converters with other system components such as energy storage units or communication modules. To achieve optimal performance, the integration in question necessitates not only technical compatibility but also a comprehension of the interconnections between the various components of the system.

Integration and System Optimization

Enhancing System Performance through Integration

The integration process in LLC converters is not just the simple assembly of components; rather, it involves the synergistic combining of a number of different subsystems and technologies in order to produce improved overall performance. For the purpose of developing a unified and effective power conversion system, this procedure involves integrating control mechanisms, power components, and feedback systems. Incorporating intelligent monitoring and control systems is a significant component of this integration that deserves special attention. With these systems, it is possible to make adjustments to the operating parameters in real time, which guarantees optimal performance even when the load circumstances and input power variations are both different.

The incorporation of LLC converters with communication interfaces and IoT technologies is yet another essential component. Consequently, this makes it possible to perform remote monitoring, control, and diagnostics, which ultimately results in increased dependability and ease of maintenance. So that the LLC converter works well in a bigger electronic system, the integration process also looks at ways to lower electromagnetic interference (EMI) and make the thermal management systems work better.

Advanced Techniques for System-Level Optimization

System-level optimization is the process of employing sophisticated technical techniques to improve the effectiveness, dependability, and functionality of the overall power conversion system with the goal of maximizing efficiency. This entails utilizing advanced simulation and modeling tools to forecast the system's behavior and determine the parameters that are ideal for its design. One method entails the use of sophisticated algorithms for power management and control. These algorithms have the ability to dynamically modify operating modes, balance loads, and control power distribution based on real-time data, resulting in significant increases in efficiency and performance.

The optimization of power flow throughout the system is another area of attention that is being addressed. We can utilize techniques like phase-shift modulation and adaptive frequency management to reduce losses and enhance the efficiency of power transfer throughout the system.

Furthermore, system-level optimization involves taking into account the requirements of the end application. For example, the LLC converter in applications like renewable energy systems or electric vehicles requires adjustment for large input voltage ranges, fluctuating load situations, and interaction with other system components like batteries and inverters.

直接登录

创建新帐号